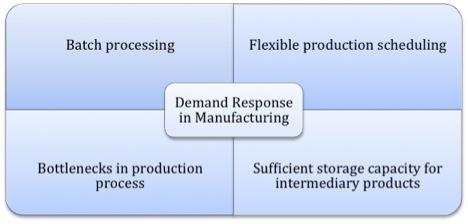

Note: A bottleneck is a stage in a process that causes the entire process and the production rate of the final product to slow down.

Let me open this by giving a few examples below from an energy-intensive industry (cement industry) and a non-energy-intensive industry (textile industry).

Example 1- DR potential in the cement industry:

In a simple form, cement production process consists of raw material (mostly limestone) grinding, high temperature kiln for clinker making, and finish grinding of clinker and some additives into cement.

The electricity use in a cement plant ranges between 90 to 150 kWh/tonne cement depending on the grinding technology, raw material properties, etc. A cement plant may have a production capacity of less than 1000 tonne per day to more than 10,000 tonne per day. Therefore, the amount of electricity use by a cement plant can be quite substantial. Over 70% of the electricity use in cement plant is used in raw material grinding and finish grinding processes.

The raw material grinding process has the following three DR-friendly characteristics:

It is a batch process

It has large storage capacity for its output (ground raw material) which last for hours and often for days

The following process (which is kiln) can be considered a bottleneck of the production. This combined with large storage capacity before the bottleneck process (#2) provides a perfect condition for DR.

The finish grinding process has the following three DR-friendly characteristics:

It is a batch process

There is a large storage capacity after kiln for ground clinker (and before finish grinding), which last for hours if not days.

If production scheduling is flexible, the operation of finish grinding to produce the final cement product can be delayed for a few hours while the previous process can continue their operation.

If we assume that an exemplary cement plant uses 120 kWh/tonne cement of which 70% (84 kWh/tonne cement) used in raw material grinding and finish grinding, and produces 3000 tonne cement pre day (125 tonne/hour), every hour of shift in the operation of both raw material grinding and finish grinding in response to a DR signal will result in 125*84=10,500 kWh reduction in electricity demand.

This is roughly equal to average daily electricity consumption of 350 U.S. residential utility customers. If only the production of either raw material grinding or finish grinding is shifted, this reduction will be cut by almost half. This is such a large DR potential that I am going to hope all utilities and cement companies are taking advantage of it.

Example 2- DR potential in the textile industry:

There are many DR potential in the textile industry. I have done substantial work on this sector and can talk for hours on EE and DR potential in different textile subsectors and process. However, since this post is getting a bit longer than I planned, I will just briefly mention two DR potentials for this industry. If you like to know more, feel free to contact me.

The first example for the textile industry is in the yarn production process. One of the main process is called “spinning process” which uses different machines such as Ring frame, Open-end machines, etc. The spinning process has the following two DR-friendly characteristics:

It is a batch process

It is a bottleneck process. Often, intermediary products that are fed into spinning machines get lined up for hours on the plant floor waiting to be processed by spinning machines. Having a proper storage capacity will allow to store enough feeding product for spinning machines and shut down the previous process, which account for around 30%-40% of electricity demand of the entire yarn production plants, for few hours during the DR period.

Another significant potential for DR in the textile industry is in wet-processing plants. Wet-processing plants conduct preparation, dyeing, printing, and/or finishing of yarn and fabric and other textile products. Many batch processes exist in wet-processing plants. Also, several processes like dryer, Stenter, or batch dyeing machines can be bottleneck processes that provide DR opportunity. Often wet-processing plants work on several different orders and products; thus, proper production scheduling can provide great DR opportunity. To take advantage of this, there needs to be high level of coordination between different departments within a plant who are in charge of production planning, energy management, paying utility bills, etc. Figure below illustrate the concept of DR potential in production processes with batch processing, storage capacity and a bottleneck process.