Deep Decarbonization Roadmap for the PVC Industry in the U.S.

Authors: Ali Hasanbeigi and Adam Sibal

The industry sector accounts for over one-third of global anthropogenic greenhouse gas (GHG) emissions. The chemical industry is the third largest CO2-emitting industry sector. The emissions from the chemical industry must be reduced sharply for the world to reach the target of the Paris Climate Agreement: to limit global warming to “well below” 2 ℃.

Polyvinyl chloride (PVC) is the world's third-most widely produced synthetic plastic polymer (after polyethylene and polypropylene). Approximately 44 million metric tons (Mt) of PVC are produced each year globally. In 2019, the U.S. production volume of PVC was around 7.2 Mt. The PVC resin manufacturing process (excluding the feedstock chemical production) accounts for around 11% of total carbon dioxide (CO2) emissions from the plastics and resins manufacturing sector in the U.S.

With the world’s growing population and the increasing need for housing and other products that use PVC, the PVC demand will likely continue to increase in the coming years and decades. This means the total energy use and GHG emissions of the PVC industry are likely to continue to increase if the current production methods are not decarbonized substantially. The United States government has a target of reducing emissions by 50%–52% below 2005 levels by 2030 and, as a part of the Paris Agreement, pledged to reach net zero emissions economy-wide by no later than 2050. The U.S. PVC industry will need to take significant actions to reduce its GHG emissions and move toward carbon neutrality by 2050.

This study focuses only on the deep decarbonization of the PVC resin manufacturing industry. The upstream (raw material production) and downstream (manufacturing of various PVC final products) are not included in this study. There are five PVC resin manufacturing companies in the US operating 14 PVC resin manufacturing plants. The U.S. PVC resin manufacturing industry used around 52.5 petajoules (PJ) of energy in 2021. This translates to around 3.9 million tonnes (Mt) of CO2 emissions in that year. Only 20% of the total energy used in the U.S. PVC resin manufacturing industry is electricity, and the remaining 80% of energy is the fuel used in boilers, cogeneration systems, and furnaces.

The goal of this study is to develop a roadmap for deep decarbonization of the U.S. PVC resin manufacturing industry. In this study, we analyzed the current status of the PVC resin manufacturing industry and developed scenarios up to 2050 to analyze different decarbonization options and pathways that can help substantially reduce CO2 emissions of the PVC resin manufacturing industry in the U.S. We included five major decarbonization options in our analysis, which are: 1) energy efficiency, 2) fuel switching to clean hydrogen, 3) limited-scale fuel switching to sustainable biofuels, 4) electrification of steam boilers, and 5) electrification of furnaces.

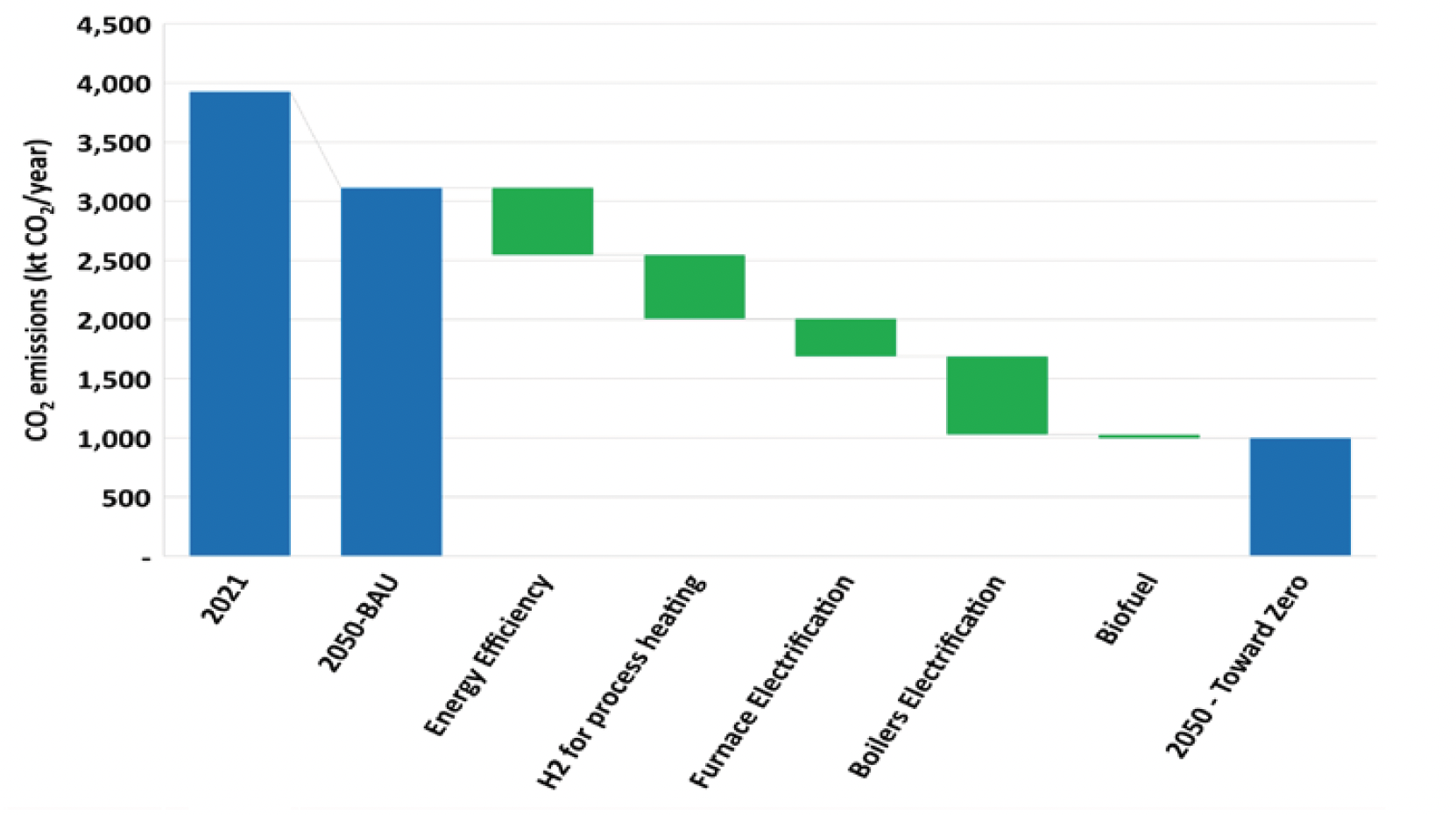

Our analysis up to 2050 shows that under the business-as-usual (BAU) scenario, which assumes no significant changes in current policies and market practices, the total CO2 emissions from the U.S. PVC resin manufacturing industry will decrease from 3.9Mt CO2 per year in 2021 to 3.1 Mt CO2 per year in 2050, a 21% decrease. This is while PVC resin production in the U.S. is assumed to increase by 20% during the same period. This is driven by the incremental improvement in energy efficiency and electricity grid decarbonization (75% clean electricity in 2050 ). Under our Toward Zero Emissions scenario, however, the annual CO2 emissions from the U.S. PVC resin manufacturing will decrease to about 1 Mt CO2 per year in 2050, around 75% reduction compared to the 2021 level (Figure ES 1). This reduction in CO2 emissions is equal to emissions from around 750 thousand passenger cars per year.

Figure ES1. Total CO2 emission in the U.S. PVC resin manufacturing industry under various decarbonization scenarios (Source: this study)

Note: The base case analysis assumes 75% of electricity will be from clean sources (renewables and nuclear) in 2050. In addition to the base case analysis presented in the main body of the report, we have also presented a scenario that assumes 100% CO2-free electricity in 2050 in Appendix 2.1.

The Electrification scenario, which assumes partial electrification of steam boilers and furnaces in the PVC resin manufacturing industry, results in a substantial annual CO2 emissions reduction in 2050. This is because boilers and furnaces account for the majority of energy used in the PVC resin manufacturing industry, and electrification of those coupled with a low-carbon electricity grid in 2050 will result in substantial CO2 emission reduction. It should be noted that while electric furnaces for the PVC resin manufacturing industry are still emerging technologies, electric boilers are fully commercial technologies and are available off-the-shelf. The main challenge to electrification adoption in the industry is the relatively lower price of natural gas in the U.S. compared to electricity prices. As the price of renewable energy production drops even further over time and the price of fossil fuels (e.g., natural gas) increases both because of market forces (such as the events in 2021 and 2022) or because of the introduction of some type of carbon price in the U.S. in coming years, the electrification technologies can become cost-competitive compared to the conventional combustion technologies.

Figure ES2 shows the contribution of each decarbonization option to the CO2 emissions reductions in the Toward Zero Emissions scenario for the U.S. PVC resin manufacturing industry in 2050. Electrification of boilers makes the largest contribution to CO2 emissions reduction, followed by energy efficiency and use the hydrogen for process heating. The contribution of furnace electrification and sustainable biofuels for heating and thermal processes is projected to be smaller because of our conservative assumptions because of techno-economic reasons, as discussed later in this report.

Figure ES2. Impact of CO2 emissions reduction options in the Toward Zero Emissions scenario for the U.S. PVC resin manufacturing industry in 2050 (Source: this study)

Note: The base case analysis assumes 75% of electricity will be from clean sources (renewables and nuclear) in 2050. In addition to the base case analysis presented in the main body of the report, we have also presented a scenario that assumes 100% CO2-free electricity in 2050 in Appendix 2.1.

Our Toward Zero Emissions scenario is technologically achievable with commercially available technologies and measures except for electric furnaces technologies which are emerging technologies requiring more research, development, and demonstration (RD&D) support. The U.S. Department of Energy can play an important role in this RD&D effort. In addition to decarbonization options included in our modeling analysis and discussed above, there are other options for reducing CO2 emissions in the PVC resin manufacturing industry and its upstream and downstream value chain, such as bio-based feedstock and PVC recycling. Some of these decarbonization measures are also qualitatively discussed later in this report.

U.S. PVC manufacturing companies play a pivotal role in driving the decarbonization of the industry by proactively adopting and investing in low-carbon technologies and practices. Companies should prioritize energy efficiency improvements, adopt fuel-switching options, such as transitioning to clean hydrogen, and implement electrification of steam boilers and furnaces. Early adoption of these technologies can provide a competitive edge and help companies stay ahead of potential future regulations. Additionally, PVC manufacturers should collaborate with stakeholders, including policymakers, research institutions, and industry peers, to identify and address barriers to decarbonization. This can involve sharing best practices, participating in joint R&D initiatives, and engaging in public-private partnerships to advance the necessary infrastructure for clean energy sources (clean hydrogen and low-carbon electricity). By taking these actions, U.S. PVC manufacturing companies can demonstrate their commitment to a sustainable future while enhancing their global competitiveness.

The U.S. government has a critical role to play in facilitating the decarbonization of the U.S. PVC industry. Industrial decarbonization policies should focus on creating an enabling environment for technology adoption, infrastructure development, and market transformation. This can be achieved through a combination of measures, such as offering financial incentives for the deployment of low-carbon technologies, funding research and development (R&D) for emerging technologies like electric furnaces. Additionally, the government can promote the use of clean energy sources, such as clean hydrogen and low-carbon electricity, by investing in the necessary infrastructure and supporting the scaling up of production capacities. The Inflation Reduction Act (IRA) aims to enhance clean energy production and infrastructure. By fostering a supportive policy landscape, the government can accelerate the decarbonization of the PVC industry while fostering growth and innovation.

To read the full report and see complete results and analysis of this new study, Download the full report from the link above.

Don't forget to Follow us on LinkedIn, Facebook, and Twitter to get the latest about our new blog posts, projects, and publications.