Electrification of Heating in India’s Textile Industry:

National, State, Cluster, and Plant-Level Assessment

India’s textile industry is one of the largest in the world, and it is a significant driver of economic growth, employment, and exports in India. However, it is also a major contributor to industrial CO₂ emissions, particularly from the use of fossil fuels like coal, lignite, and petroleum fuels for thermal energy. As India pursues its Net Zero target and industrial decarbonization goals, electrifying thermal energy in the textile industry presents a promising solution with both economic and environmental benefits.

This report evaluates key electrification technologies that can electrify process heating, typically provided by fossil fuel-fired boilers, in India’s textile industry: electric boilers (steam and thermal oil) and industrial heat pumps that generate steam. Electric boilers offer a mature, commercially available pathway for decarbonizing thermal energy in the textile industry. They are highly efficient, with operating efficiencies up to 99%, and have lower capital, installation, and maintenance costs than conventional boilers. Industrial heat pumps offer even greater efficiency gains, using electricity to transfer heat rather than generating it from combustion or electrical resistance. They can deliver multiple units of heat for every unit of electricity consumed. These efficiency gains make heat pumps particularly attractive from both an emissions and energy cost perspective, even when electricity prices or grid carbon intensity are relatively high. Commercially available heat pumps can reach temperatures up to 170°C, sufficient for most textile processes.

Textile wet-processing is one of the most energy-intensive processes in textile production, consuming the greatest share of thermal energy and fuel in a typical composite textile plant (Hasanbeigi and Zuberi 2022). In India, coal represented 81% of fuel use for textile wet processing, with biomass representing 18% and petroleum products the remaining 1% (Vasudha Foundation 2025). Greenhouse gas emissions (GHGs) from India’s textile industry were conservatively estimated at approximately 49 million tons (Mt) CO2 for 2019-2020 (MSPI 2025, Vasudha 2025). India’s top three textile-producing states – Gujarat, Tamil Nadu, and Maharashtra, all have significant textile wet processing and associated emissions. The extensive use of lignite and imported coal in Gujarat’s textile clusters leads to a high carbon intensity of thermal energy use in Gujarat’s textile sector. In Maharashtra, coal is also the dominant fuel, although some textile clusters derive a large share of their fuel from woody biomass sources such as firewood (Vasudha 2025), a practice that raises sustainability concerns. In Tamil Nadu, thermal energy demands of wet-processing continue to drive coal and biomass fuel consumption, as well as petroleum products like fuel oil used in boilers. Other major processes in the textile industry, like spinning, weaving, knitting, and garment manufacturing, primarily use electricity. The textile industry in India is also an active consumer in the renewable energy market, using either on-site rooftop solar or power purchase agreements.

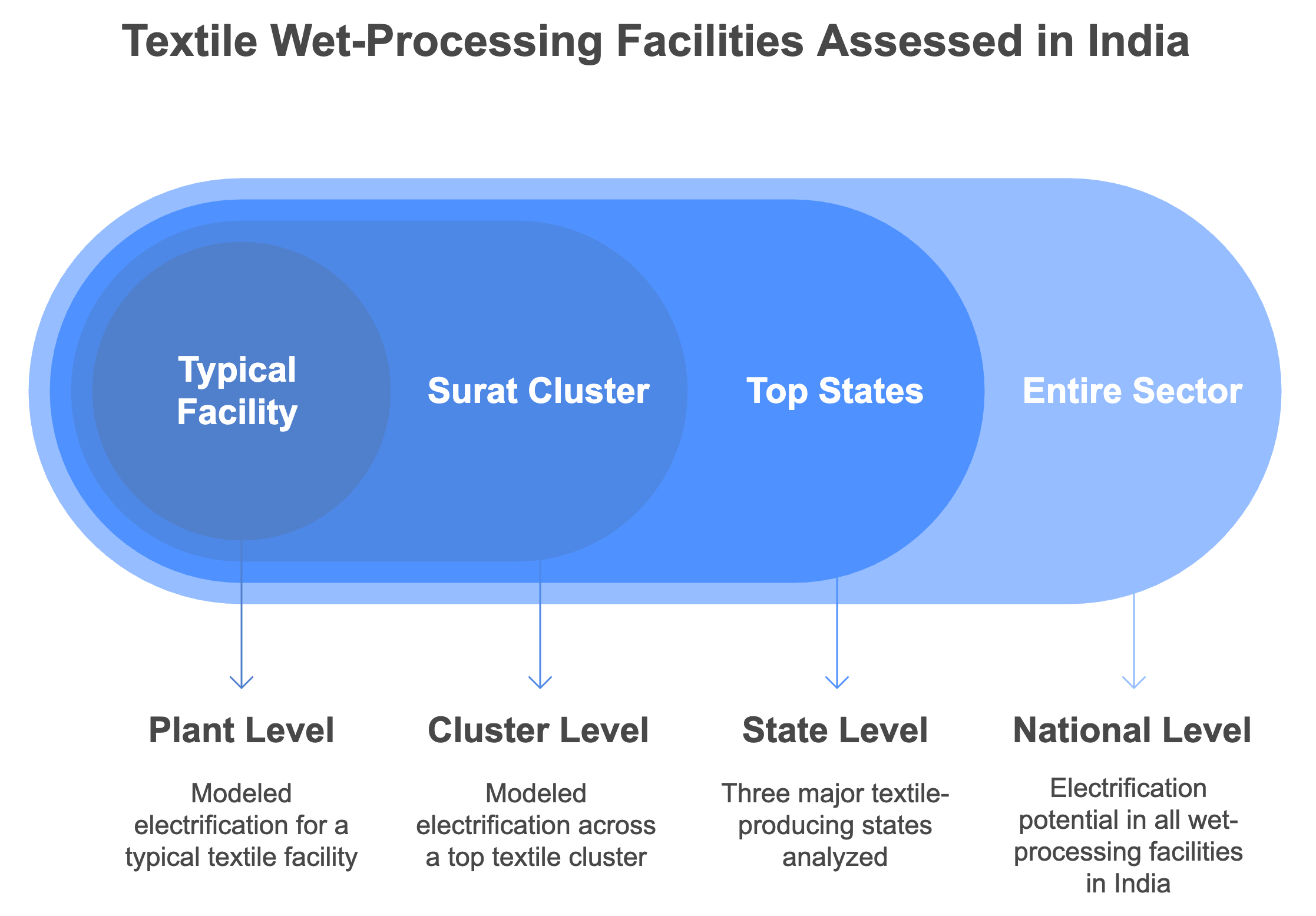

In this study, we evaluate the potential for electrification of textile wet-processing facilities at the national level; for the three aforementioned states; for one textile cluster, the Surat cluster in Gujarat, which has a concentration of wet-processing units and is heavily reliant on lignite and imported coal (Bureau of Energy Efficiency 2013); and at the facility level for a typical wet-processing facility in India (Figure 1).

Figure 1. Scope of the textile industry electrification assessment in this study

The benefits of electrifying heating at textile facilities can be strengthened by procuring low-cost renewable energy through mechanisms such as onsite generation, open access agreements, renewable energy certificates, and green tariffs that are increasingly available across India. India has emerged as a global leader in renewable energy deployment, underpinned by ambitious national targets, falling technology costs, and an increasingly competitive developer landscape. India is estimated to have 7 GW of captive renewables capacity, with textile facilities can increasingly take advantage of at lower costs than for grid electricity. This report also analyzes the corporate RE procurement landscape in India and for Gujarat, Maharashtra, and Tamil Nadu.

To evaluate the impacts of electrification in India’s textile industry, we developed a techno-economic model to characterize the baseline energy consumption and emissions profile for conventional steam and thermal oil boilers in textile wet-processing plants across India, the three studied states, the Surat cluster, and for a typical facility. We then evaluated how this profile changes following electrification with electric steam boilers or heat pumps, and electric hot oil boilers. Impacts on energy use, CO₂ emissions, and heating costs were modeled for the years 2030, 2040, and 2050, based on projected electricity and fuel prices and emissions factors. Because adoption of electrification technologies will be gradual over time, we also assumed adoption rate scenarios for the national, state, and cluster level, choosing a slower Base Case Adoption scenario and a more rapid Advanced Adoption scenario. We also developed two electricity supply scenarios that vary in how much procured RE is in an electrified facility’s electricity supply, versus grid electricity (the Baseline and Ambitious Grid Plus RE Procurement scenarios).

We find that all electrification technologies can reduce annual energy use for steam or thermal oil heating in India’s textile facilities. At the facility level, with full electrification, electrified technologies can reduce energy use and emissions significantly. At the cluster, state, and national levels, in 2030, when adoption rates are predicted to be low, these energy savings are very small, but increase over time with higher adoption rates. We also find that electrification technologies can significantly reduce emissions when adopted at scale and paired with even Baseline scenario levels of RE. Figure 2 shows emissions results for electric steam boilers, demonstrating that by 2040, with the assumed adoption rates increasing, electric boilers begin to significantly displace emissions from conventional steam boilers while maintaining the same level of textile production. By 2050, under the Advanced Adoption scenario, steam boiler emissions could be eliminated across India’s textile industry due to the use of 100% RE under the Ambitious Grid Plus RE Procurement scenario. The report contains additional state- and cluster-level analysis.

Figure 2: Annual CO2 emissions for conventional vs. electric steam boilers in India’s textile industry, Base Case and Advanced Adoption scenarios for the entire textile industry in India (Source: this study)

Note: The emissions from biomass use in conventional steam boilers are presented in dashed lines to represent the variability in emissions depending on biomass source. For unsustainable biomass sources, we assume the IPCC emissions factor for direct combustion of biomass (Intergovernmental Panel on Climate Change 2006). If biomass is sourced from sustainable, carbon-neutral sources, the dashed blue bar would be eliminated.

Note: Emissions under the 100% electric steam boiler adoption scenario - Ambitious Grid Plus RE Procurement scenario in 2050 are zero.

We conducted a similar analysis for industrial steam-generating heat pump applications in India’s textile industry. Due to their high energy-saving potential and the increasing integration and procurement of RE, heat pumps can significantly reduce emissions from steam generation over time. As shown in Figure 3, greater adoption of heat pumps progressively reduces emissions from conventional steam boilers. By 2050, if heat pumps are fully adopted across India’s textile industry, emissions could be nearly eliminated under the Baseline Grid Plus RE Procurement scenario, even with 50% of electricity still sourced from the grid. Under a scenario with full renewable energy procurement, emissions would drop to zero.

Figure 3: Annual CO2 emissions for conventional steam boilers vs. steam-generating heat pumps in India’s textile industry, Base Case and Advanced Adoption scenarios for the entire textile industry in India (Source: this study)

Note: The emissions from biomass use in conventional steam boilers are presented in dashed lines to represent the variability in emissions depending on biomass source. For unsustainable biomass sources, we assume the IPCC emissions factor for direct combustion of biomass (Intergovernmental Panel on Climate Change 2006). If biomass is sourced from sustainable, carbon-neutral sources, the dashed blue bar would be eliminated.

Note: Emissions under the 100% heat pump adoption scenario - Ambitious Grid Plus RE Procurement scenario in 2050 are zero.

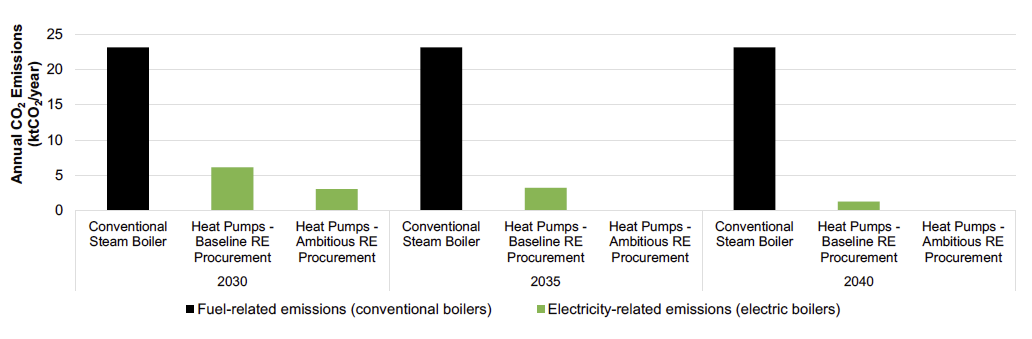

At the facility level, electrification can significantly reduce annual energy use and CO2 emissions (Figure ES4). We modeled a typical textile wet-processing facility in India that fully electrifies its steam (either electric steam boilers or heat pumps) and thermal oil heating needs. We estimated that adoption of electric steam boilers could save about 17 GWh per year, a reduction in annual energy use of 26%. Alternatively, heat pump adoption at a typical textile facility in India could save 48 GWh/year due to their higher efficiency. For the electrification of thermal oil boilers, energy savings would be about 8 GWh per year for a typical textile facility. All electrification technologies can reduce emissions when paired with RE; heat pumps lead to the most significant near-term emissions reductions due to their high efficiency. With 100% RE procurement, roughly 23 kt of CO2 emissions from conventional steam boilers could be eliminated.

Figure 4: CO2 emissions from conventional steam boilers vs. heat pumps at a typical textile wet-processing facility in India, Baseline and Ambitious RE Procurement scenarios (Source: this study)

Note: These results are for an individual facility adopting heat pumps for all steam-based process heating needs. No adoption rate is applied, as it is for the national, state, and cluster level results in the previous chapters.

We also analyzed energy costs, encompassing fuel, electricity, and carbon costs from an assumed carbon price that would be adopted in India based on current policy proposals. For electric steam and thermal oil boilers, electricity costs are a challenge in the near term, although some states, like Tamil Nadu, have a relatively more favorable electricity-to-fuel price ratio that lessens this challenge. For heat pumps, however, due to their higher efficiency, energy costs are expected to be significantly lower for heat pumps in 2030, especially under the Ambitious Grid Plus RE procurement scenario with integration of more low-cost RE.

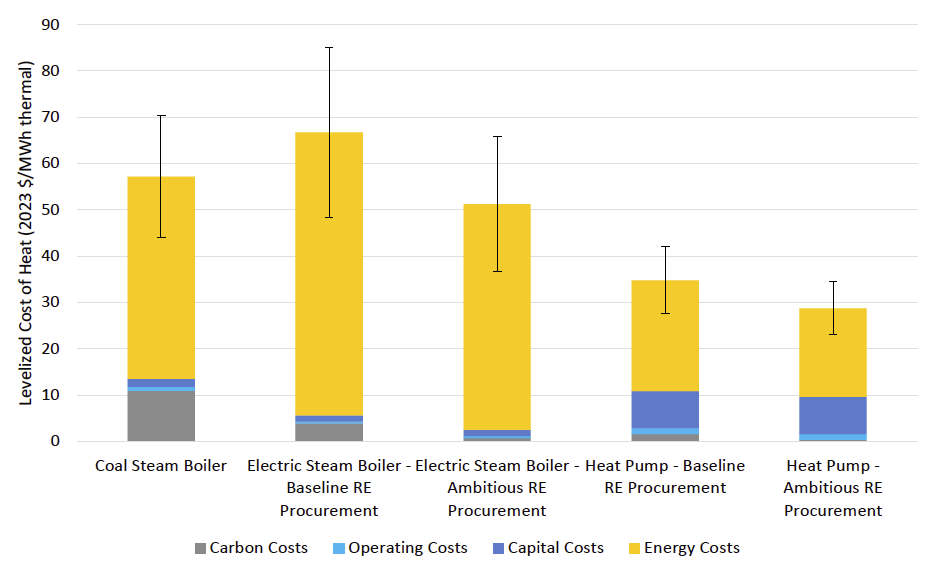

We also evaluated the total CAPEX for each electrification technology for steam generation compared with conventional steam boilers at the national, state, and cluster level, collecting data on typical investment costs per unit of capacity for different steam generation technologies in India. We estimate that fully electrifying India’s textile industry could cost $930 million if pursuing electrification with electric steam boilers, or $5.6 billion if using steam-generating heat pumps, compared to a reference of new coal boilers, which would cost $1.4 billion. Given the high capital costs of heat pumps, we also wanted to evaluate lifetime technology costs, taking into account the lower energy costs of heat pumps.

Thus, we also estimated the levelized cost of heating (LCOH) for each steam-generating technology. The LCOH takes into account capital expenditures (CAPEX) and operational expenditures (OPEX), as well as energy costs, costs due to carbon pricing, and the cost of capital. In order to estimate the LCOH for each technology, we adapted our model to represent different steam-generating technologies for a typical textile wet-processing facility in India with an annual thermal heating requirement of 50,000 thermal megawatt-hours (MWh_th). The figure below presents the results of our LCOH analysis for a typical facility in India. Heat pumps have a lower LCOH than coal boilers under both electricity supply scenarios. Even though their capital costs are significant, their high efficiency leads to significantly lower lifetime energy costs, especially when leveraging procured RE. We also modeled levers to lower the LCOH of electric steam boilers, which have a higher LCOH than new coal steam boilers for India under the Baseline Grid Plus RE procurement scenario. The most effective lever for lowering the lifetime costs of electric boilers is energy cost subsidies.

Figure 5: Levelized cost of heating for steam-generating technologies for a typical textile wet-processing facility in India

Note: Error bars represent an energy price sensitivity of +/- 30%

For textile facilities that seek to capture the benefits of electrification, this report also provides next steps to understand how textile plants can begin the process of transitioning to electrified heating. The report presents implementation guidelines for an effective transition, beginning with the implementation of electrification, and then covering how facilities in India can procure RE to maximize the benefits of electrification.

Lastly, we present an action plan to accelerate textile sector electrification in India. The national government should provide targeted grants and capacity-building programs through agencies like the Ministry of Textiles, MNRE, BEE, and SIDBI, while enforcing uniform Green Open Access rules and streamlined RE banking. State governments, such as those in Maharashtra, Gujarat, and Tamil Nadu, should implement electricity tariff incentives, training programs, and stable regulatory frameworks to support the adoption of electric boilers and heat pumps. Textile manufacturers and apparel brands should reduce thermal demand, pilot electrification projects with RE procurement, and collaborate on financing and advocacy efforts. Power sector stakeholders, including DISCOMs and RE developers, should modernize infrastructure in textile clusters, offer favorable TOU tariffs, create streamlined open access portals, and co-develop hybrid RE supply models tailored to the textile industry’s needs. The figure below summarizes these recommendations.

Figure 6: Summary of the action plan for textile electrification in India by stakeholders

To read the full report and see complete results and analyses, download the full report from the link above.

Interested in information and decarbonization studies on the global textile and apparel industry? Check out our list of textile industry publications and tools on the Textile Sustainability Hub.

Don't forget to follow us on LinkedIn and X to get the latest about our new blog posts, projects, and publications.